£0.00

0Castors and Wheels – Technical Reference Guide

This guide presents detailed technical information on castors and wheels, compiled from content previously hosted on the H Varley Castors website. It remains relevant for engineers and buyers who require additional information on product choice, use, configuration and more.

Index

- 1.0 Units of Measure

- 2.0 Loadings

- 3.0 Lubrication

- 4.0 Castor Types

- 5.0 Castor Uses

- 6.0 Castor Terminology / Definitions

- 7.0 Fixing Types

- 8.0 Adaptations

- 9.0 Wheel Types

- 10.0 Wheel Terminology / Definitions

- 11.0 Wheel Bearings

- 12.0 Chemical Resistance

- 13.0 Castor and Wheel Configurations

- 14.0 Power Towing Applications

1.0 Units of Measure

All dimensions are given in millimetres (mm), and all load ratings are expressed in kilograms (kg) unless otherwise stated.

2.0 Loadings

Load ratings are based on typical use in truck and trolley applications with intermittent operation. However, working conditions can vary greatly. Special considerations may apply in the following situations:

- Uneven floor surfaces

- Ramps, cracks, gullies, or door guide rails

- Track or turntable use

- Power towing or driven wheels/rollers

- Any application other than manual propulsion

In such cases, a castor or wheel with a significantly higher load capacity than expected may be necessary. For tailored advice, please contact our technical sales team.

3.0 Lubrication

All moving parts are treated with high-quality grease to form a protective layer and reduce wear from metal-to-metal contact. Many swivel castors are fitted with swivel head seals to minimise maintenance.

3.1 Routine Lubrication

Where lubrication is required, use a pressure oil gun to ensure the lubricant reaches the kingpin head—especially on single ball race castors. Heavy-duty castors and wheels may include grease nipples or drilled axle bolts for easier maintenance.

Note: Nylon wheel bushes are virtually self-lubricating but benefit from occasional lubrication in dusty environments.

3.2 Operating Temperatures

- A general-purpose lithium-based grease is used in most castors, suitable for -30°C to +130°C.

3.3 Low Temperatures

At low temperatures, grease thickens, which can reduce swivel and rolling performance. For these conditions, use double ball race castors with low-temperature grease.

3.3 High Temperatures

In high-temperature environments—such as forced draught ovens—regular grease replenishment is essential. Grease (or grease components) may volatilise, leading to carburisation. For these applications, contact us for more details.

4.0 Castor Types

Castors are generally categorised into two main construction types:

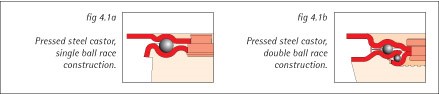

4.1 Pressed Steel

Pressed steel castors use a single or double ball bearing swivel raceway. The ball bearings run in tracks formed within the fork and top plate pressings, secured together by a heavily riveted steel kingpin.

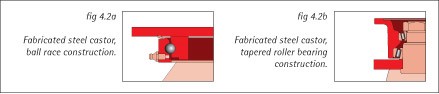

4.2 Fabricated Steel

Fabricated castors are built from precision-machined heavy steel forgings, incorporating tapered roller or ball bearing races. The fork legs are welded to the swivel head forging, resulting in an extremely strong structure ideal for heavy-duty loads.

5.0 Castor Uses

Castors typically fall into two application categories:

5.1 Frequent Movement

Used on trucks, trolleys, and trailers regularly moved with loaded goods. Key requirements:

- Low tractive resistance

- Free swivelling for easy manoeuvrability

- Recommended wheel diameter: minimum 100 mm, preferably 150 mm+, regardless of load rating

5.2 Occasional Movement

Fitted to equipment that is usually stationary but may need occasional repositioning.

- Smaller castors may be sufficient

- Often used at full rated load

6.0 Castor Terminology / Definitions

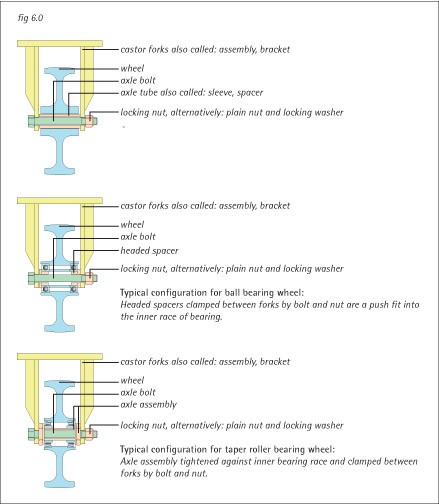

A castor comprises a wheel fitted within either swivelling or fixed forks. The wheel is typically retained between the fork legs using an axle set. The following terms are commonly used:

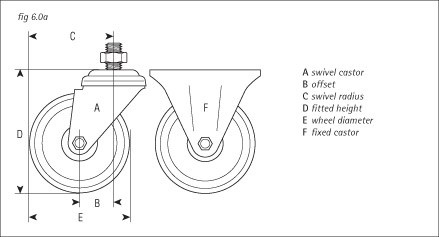

- 6.1 Swivel Castors: The wheel housing can freely rotate around a vertical axis. The wheel axle is offset from this axis, enabling smooth changes in direction.

- 6.2 Fixed Castors: The wheel is housed in a non-swivelling fork, offering straight-line movement only.

- 6.3 Wheels: The rotating centre of a castor, which contacts the ground directly or via an outer tyre.

- 6.4 Offset: Also known as “trail” — the horizontal distance between the wheel axle centre and the swivel bearing’s vertical axis.

- 6.5 Swivel Radius: The horizontal distance from the vertical swivel axis to the outer edge of the wheel (or brake pedal if it protrudes further).

- 6.6 Fitted Height: The height a castor raises the equipment it’s fitted to. May not match the overall castor height, depending on fixing type.

- 6.7 Wheel Diameter: The total diameter of the wheel, including any tyre.

- 6.8 Tractive Resistance: The effort required to move equipment fitted with castors. Expressed as a percentage of the total load:

- Hard tread wheels: < 1%

- Polyurethane tyred wheels: ~2%

- Rubber tyred wheels: ~3.5%

Note: Based on 200 mm roller bearing wheels. A human can typically exert a horizontal force of 12 kgf, increasing to 18 kgf from a standstill. Polyurethane wheels may require double the force to start movement after standing under load, with momentary resistance spiking up to 7× normal.

7.0 Fixing Types

Fixings refer to how a castor is attached to equipment. The main types include:

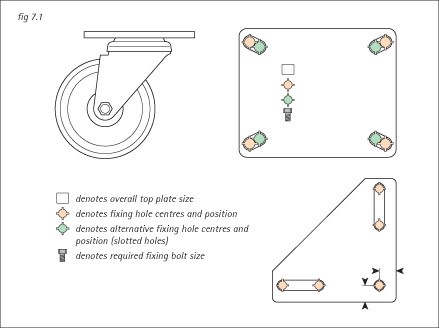

7.1 Plate Fixing

- Typically a rectangular plate with four fixing holes

- Alternatives: 3-hole triangular or 2-hole rectangular plates

- ISO 2184 standard fixing hole centres:

- Class 2: 80 mm × 60 mm

- Class 3: 105 mm × 80 mm

- Class 4: 140 mm × 105 mm

- Some fixings use slotted holes to accommodate DIN or North American standards

Tip: Always fit to ISO standards when possible, avoiding bolt placement mid-slot.

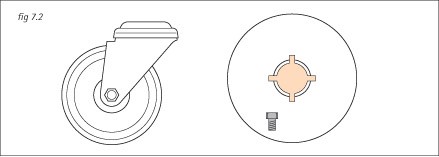

7.2 Bolt Hole / Single Bolt Fixing

A single central hole in a circular top plate. Can accept a bolt from below or attach to a pre-mounted stud.

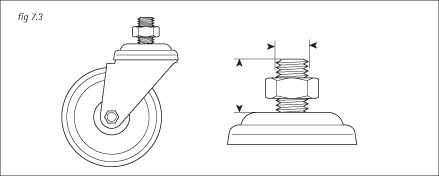

7.3 Threaded Stem Fixing

A fixed threaded stud protrudes from the castor swivel head. Usually supplied with a loose nut (check availability).

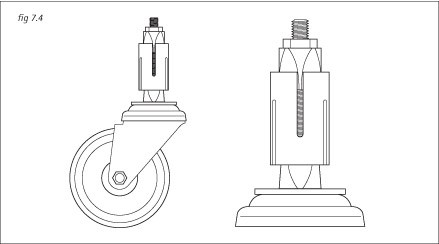

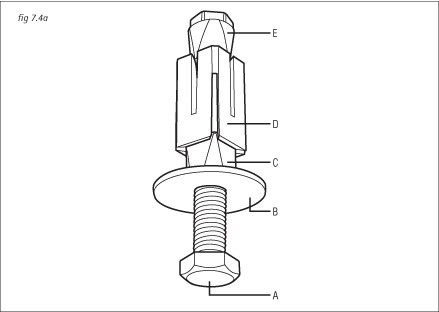

7.4 Expanding Adaptor

For fixing into square or round tube. Tightening the bolt inside the swivel head expands the adaptor within the tube.

Assembly instructions:

- Assemble the bolt (A) to the castor so that the bolt head is inside the swivel head and the thread protrudes from the top of the castor.

- Slide washer (B) over the bolt.

- Slide bottom cone with plain hole (C) over the bolt so that the smaller square end is facing up.

- Slide sleeve (D) over the bolt. The sleeve is the same at each end so orientation is not required.

- Align flats on the bottom cone with flats on the inside of the sleeve.

- Screw the top cone with threaded hole (E) down the bolt so that the small square end aligns with flats on the inside of the sleeve.

- When correctly fitted, sleeve and cones rotate together and are in line but loose and ready for fixing.

To fix the castor with the expander assembly, offer up the tube and push the expander assembly fully home so that the castor is in contact with the base of the tube.

Tighten the bolt to ensure the castor is securely fitted:

-

- 10 Nm for M12 bolts

- 8 Nm for M10 bolts

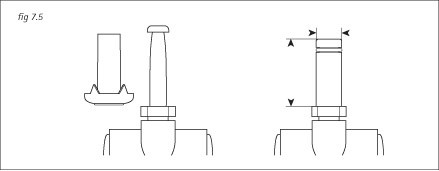

7.5 Furniture Fixings

- Peg-and-socket for wood

- Push-fit circlip stem for metal (e.g. chair bases)

- Common on twin wheel or ball-type furniture castors

8.0 Adaptations

Various adaptations are available to suit specific application needs:

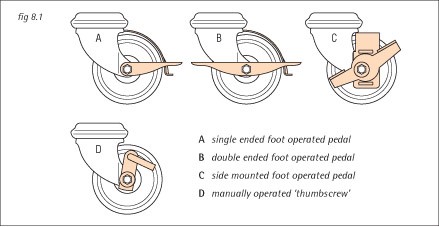

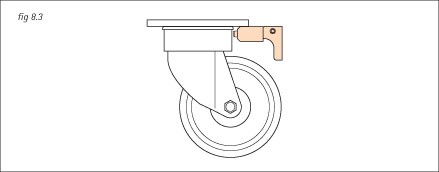

8.1 Wheel Brake

Foot-operated pedal presses a pad against the wheel tread. Manual options include a thumbscrew or cranked pin against the wheel centre.

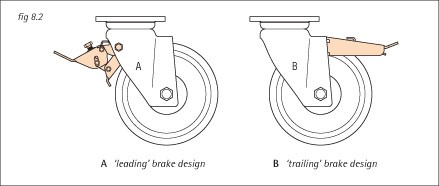

8.2 Total Stop Brake

Also called combined swivel and wheel brake. A single foot-operated pedal locks both the swivel head and wheel. Can be mounted in either leading or trailing position.

8.3 Directional Lock

Hand or foot lever locks the swivel head in a fixed direction. Available as:

- 2-station (180°)

- 4-station (90°)

Caution: If a 4-station lock is left engaged but not properly aligned, it may lock unexpectedly at 90°, causing a sudden swerve or damage.

Supplied either welded or in kit form.

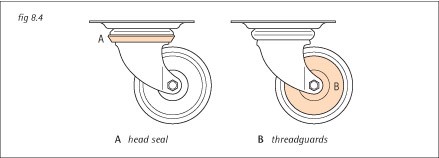

8.4 Swivel Seal / Threadguards

Rubber head seals prevent dust and debris from entering the swivel head. Threadguards are especially useful in textile environments to avoid thread buildup.

9.0 Wheel Types

Wheels are typically grouped into:

9.1 Resilient Tread Wheels

- Made from rubber or polyurethane

- Benefits: quiet operation and floor protection

- Downsides: increased tractive resistance (up to 3× more than hard wheels)

Polyurethane highlights:

- Load capacity close to cast iron

- Highly resistant to tearing and abrasion

- Lower tractive resistance than rubber

- Impervious to mineral oils and grease

- Excellent for high-load power towing applications

9.2 Hard Tread Wheels

Easier to push and often the first choice for maximum mobility.

- Cast iron: Strongest and most durable; very low tractive resistance but noisy and potentially floor-damaging

- Nylon (injection moulded or cast):

- Quiet and lightweight

- Resistant to water and self-lubricating in wet conditions

- Load capacity close to cast iron

- Temperature range: -40 °C to +80 °C

- May require 25% derating of load rating under very harsh conditions

- Unlikely to damage floors

- High-temperature alternatives: Thermoplastic and phenolic resin wheels

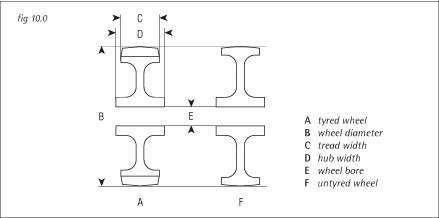

10.0 Wheel Terminology / Definitions

- 10.1 Wheel Diameter: The total external diameter of the wheel, including any tyre.

- 10.2 Tread Width: The width of the wheel’s tread at its widest point.

- 10.3 Hub Width: The full width of the wheel at the hub.

- 10.4 Bore: The internal diameter of the wheel bore, or of the bearing if fitted.

11.0 Wheel Bearings

There are four main types of wheel bearings:

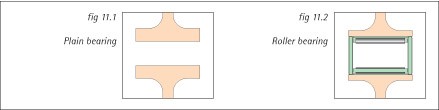

11.1 Plain Bearing

Fine for many applications where maximum mobility is not essential.

- Simple plain bore with no rolling elements

- Requires regular lubrication, especially in cast iron wheels, via the grease nipple or drilled hole in the axle bolt

- Nylon wheels are grease-treated on assembly and usually maintenance-free in clean environments

- Dusty or gritty conditions can cause squeaking and axle tube wear

11.2 Roller Bearing

No increase to load capacity but keep rolling resistance to a minimum and prolong working life.

- Pre-greased at assembly

- Often maintenance-free in light-duty applications

- Heavy-duty designs include provisions for lubrication

- In cast iron wheels: runs on a hardened steel split sleeve to extend life and reduce rolling resistance

- In plastic-centred wheels: no split sleeve needed

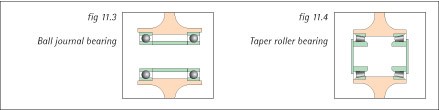

11.3 Ball Journal Bearing

Essential for power towing applications.

- Suitable for high radial and moderate axial loads

- Very low rolling resistance

- Shielded to retain grease and exclude grit

- Includes a spacer tube to support the inner races which are clamped together end-wise on —requires no adjustment

- Used in manual and low-speed power towing applications

11.4 Taper Roller Bearing

For the heaviest loads and essential for power towing applications.

- Best for very heavy loads with high radial and high axial stresses

- Hardened bearing cups and cones for extended life

- Bearing adjustable at installation

- Fitted with grease seals to retain grease and exclude grit etc

- Fitted with grease nipples for replenishment in harsh conditions

12.0 Chemical Resistance

If your application involves exposure to chemicals, check compatibility for each castor and wheel component. Material resilience varies widely.

Tip: Contact the technical sales team with full chemical exposure details for tailored advice.

13.0 Castor and Wheel Configurations

Correct configuration of fixed and swivel castors is essential for performance and wear minimisation.

ISO guidance: Top plate bolt holes allow 1 mm clearance for bolts up to 12 mm, and 2 mm for larger bolts. This tolerates minor fabrication errors but can lead to misalignment if not tightened carefully—causing drag and excessive tyre wear.

13.1 Two Swivel / Two Fixed Castors

- Most practical setup for industrial use

- Combines manoeuvrability and accurate, straight-line steering

- Fixed castors should lead during movement

13.2 Four Swivel Castors

- Excellent manoeuvrability

- Best for environments requiring frequent side motion or tight turns

- Difficult to guide straight, especially under load or on uneven ground

- Not recommended for ramps

- Add directional locks to two castors to improve tracking

13.3 One Swivel / Two Fixed Castors

- Cost-effective for small, light trolleys

- Requires even load distribution for stability

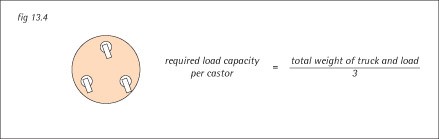

13.4 Three Swivel Castors

- Very manoeuvrable

- Challenging to control on straight runs and on uneven ground

- Best suited for barrel dollies or small portable machines

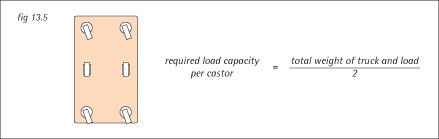

13.5 Four Swivel / Two Fixed Castors – Centrally Pivoting

- High load capacity with good manoeuvrability & stability

- Used on long, heavy-load trolleys

- Fixed castors (or axle-mounted wheels) packed ~25 mm higher to pivot on central wheels

- Base must be robust

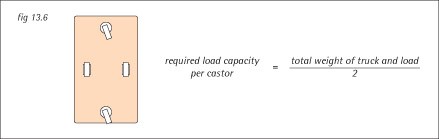

13.6 Two Swivel / Two Fixed Castors – Centrally Pivoting

- Excellent for confined areas

- Balanced load distribution required

- Similar to 13.5 but with fewer components

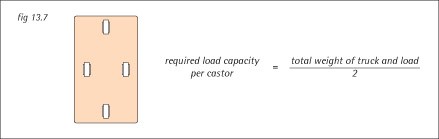

13.7 Four Fixed Castors – Centrally Pivoting

- Budget-friendly option for long, straight routes with occasional turning

- Central fixed (or axle mounted) castors packed by ~25 mm to pivot the trolley

- Even load distribution is essential for stability

14.0 Power Towing Applications

Most pressed steel castors are intended for manual use only. Power towing places significantly higher stress on castor components and so fabricated castors are strongly recommended for these applications.

Fabricated castors are engineered for:

- Operating speeds up to 6 kph

- Use in good, controlled conditions without major obstructions

Important: Even small steps, drain covers, or joints in concrete can cause severe impact loads. If a castor approaches these at an angle rather than head-on, it may rotate sideways and fail instead of climbing over the obstruction.

In towing scenarios involving trains of multiple trailers, a single castor may absorb the force generated by the entire combined mass—including the towing vehicle. This greatly increases the risk of failure.

Multiple trailers: As power towing becomes more common, it may be desirable to tow multiple trucks or trailers, one behind the other. Towing like this, in train, can make the impact load even worse as just one castor may have to withstand the entire force of the whole train including the tractor.

While traditional turntable axles are sometimes used in this application:

- They are expensive

- They reduce stability when at right angles to the truck axis

- They pose a jack-knifing risk

Alternative to Turntable Axles: Fabricated castors offer a simpler, more robust solution, provided the towing setup is properly configured to prevent cutting-in, especially in narrow gangways.

14.1 Castor Configurations for Power Towing

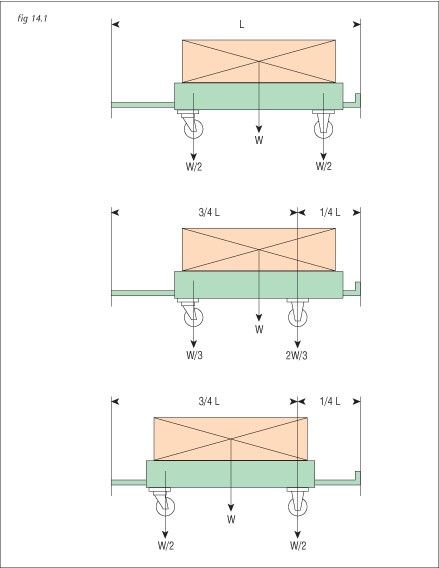

To optimise tracking in towed trailer trains, castor positioning and drawbar design are critical.

- Rigid couplings (e.g. pin links) between trailers require precise positioning to follow a true track

- Best practice: Determine the total length of the truck from front to rear coupling pins. Calculate 25%-33% of this length. This calculated length should then be used a distance guide from the fixed castor centre-line to the rear coupling.

- In other words, this moves the fixed castors forward. This improves tracking accuracy but may reduce wheelbase and increase the shared load disproportionately on the swivel castors

Solution: Use an extended drawbar at the rear of the trailer to maintain balanced load distribution while achieving optimal tracking.