£0.00

0Best Castors for the Waste Processing Industry

Within the waste processing industry, waste is collected, stored and transported between different areas and locations. A multitude of variously sized containers are used to facilitate this, ranging from waste bins, wheelie bins and carts to skips that are designed to hold larger and heavier loads.

Waste handling skips take a lot of punishment, but they are specially designed and built for operating in very demanding conditions. As such, they are heavy and unwieldy. Whilst they are often manoeuvred into position by lifting equipment or a pallet truck, they also regularly need to be manually moved into a final position. In addition, waste processing can also involve other large and heavy equipment such as shredders, balers and compactors which typically also need to be moved around to different locations within a site.

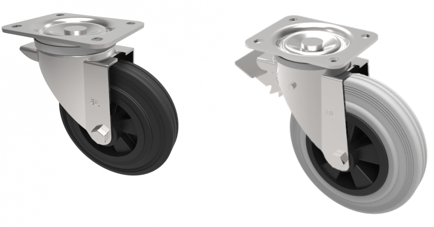

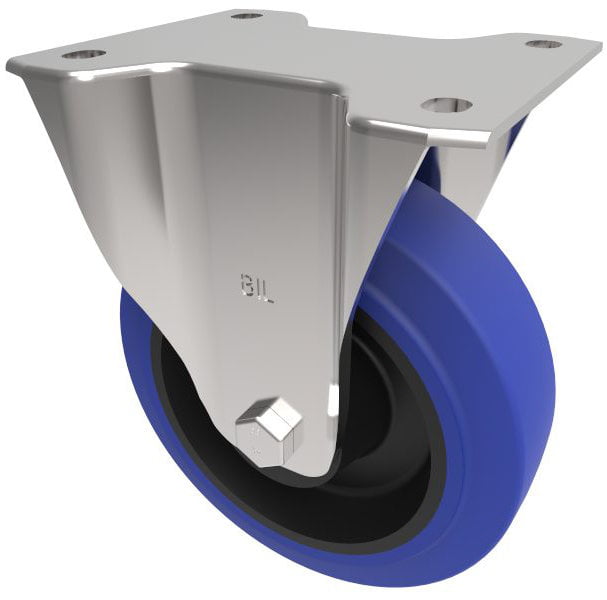

Castors are used to provide the necessary final stage mobility for waste processing equipment, allowing the items to be easily and safely moved around between areas. A couple of examples of suitable castors for use in the waste processing industry are shown below;

See our complete range of material handling castors here.

Understand your requirements

Choosing the best castors for waste processing units will ultimately depend on the specific requirements of your application. Some of the factors that you will need to consider when the appropriate castors for your waste processing equipment include:

- Load capacity – it is vital to ensure that the castors you select are suitable for the weight of the equipment and the waste it will be carrying. At BIL, our waste processing castors carry loads ranging from 140kg to 350kg per castor.

- Castor material – castors and wheels can be made from a variety of materials and can be designed for use in specific environments such as wet or corrosive conditions. For example, our waste bin castors are zinc plated for corrosion resistance.

- We offer six different options for wheel materials:

- black rubber on pressed steel

- black or grey rubber on polypropylene

- blue elastic rubber 65 shore A

- polyurethane on cast iron or nylon

- black rubber on pressed steel

- Castor type – there are several options to consider around the type of castor to be used – does your application require swivel or fixed wheels, with or without brakes? We also have both leading and trailing brake options.

The swivel option allows the waste processing equipment to be turned in different directions more easily whereas the fixed castor will make it easier to move the equipment in a straight line. Swivel castors can also be equipped with brakes, so that they act like fixed castors when necessary, or as total brakes to keep the equipment in place when it is not being moved. - Mobility – it is important to consider the surfaces that the equipment will be used on and select castors that will best handle that surface. For example, castors with larger wheels are typically better suited for use on rough or uneven surfaces, while smaller wheels may be suitable for smooth, level surfaces.

Why buy your waste material handling castors from BIL?

BIL are ISO 9001:2015 accredited as a manufacturer, designer and developer of castors and wheels and our Quality Management System shapes everything that we produce.

Testing and quality control is standard practice at BIL and our products have been extensively field tested to ensure they perform in the real world and not just in test environments.

Full batch traceability is incorporated in our systems to track every single component and materials back to source. Final checks prior to dispatch ensure that our renowned superior build quality on all wheels & castors remains consistently high.

The BIL brand stamp is a guarantee of the highest quality and our assurance that our products are built to last.

BIL are confident that we can provide what you want, when you want it and at really competitive prices.

The filters on our site will help you to select the ideal castor for your needs. However, if you are unsure which castor to select, or have any questions, then our experts are always on hand, and happy to advise you on selecting the most suitable castors for your needs. Indeed, if your requirement can’t be met from our pre-existing ranges, we can look manufacturing custom built castors just for you.

Please call us today on 01249 822 222 or email us at; sales@bilgroup.co.uk to discuss your requirements. We look forward to speaking to you.